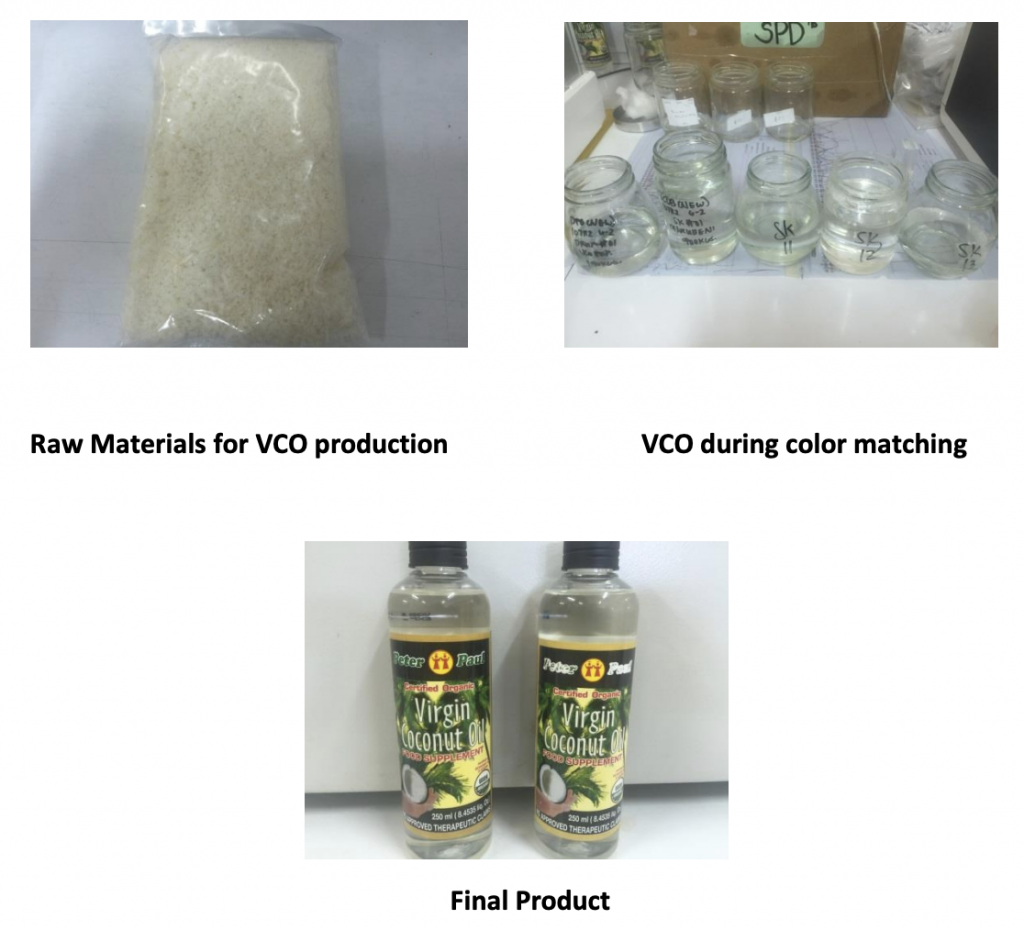

Virgin Coconut Oil are oils which comes from coconut meat. The main difference between an

ordinary coconut oil and virgin coconut oil (VCO) is the process of extraction. VCOs are

produced using the cold process as such there is no heat applied when extraction is done. The

absence of heat during extraction is very important because this preserves the Lauric Acid

content of the oil and Medium Chain Triglycerides (MCTs). Unlike ordinary coconut oil which

undergoes heat application in its production process wherein Lauric Acid and MCTs are partly

destroyed. Lauric acid and MCTs have a lot of health benefits like it can act as an antibiotic, kill

viruses and other pathogens. It has also a therapeutic effect on brain disorders and can help

burn more fat in the body.

Virgin Coconut Oils produced in the Philippines are exported to Europe and the USA. Basically

they have a standard color approved by their customers. Each customers have different

standards colors but in general they maintain a CIE delta E equals to 0.5. What the quality

control department does is that they get the delta E for each batch that they produced. If the

delta E is above 0.5 they will reject the batch. This rejected batch will undergo reprocessing

until they achieved a delta E of 0.5. What they normally do to the rejected batch is they will mix

it with the new batch to achieve the desired delta e.

Color matching of Virgin Coconut Oils involves the following steps:

1) Samples are placed in a 10ml cuvette for transmittance measurement using the CM-5.

2) Settings is D65 and 10o

3) Standard readings are saved in the instrument

4) Each production batch is measured. CIE delta E of 0.5 is the maximum tolerable delta E.

5) If the sample is below delta E of 0.5 then the batch will undergo packaging

6) If the delta E is greater than 0.5 the batch is rejected and will undergo reprocessing i.e

the batch will be mixed with newly produced batch to achieved the desired delta E.