Wheat Flour

Flour color is an important commercial factor. Color is associated with flour quality and is dictate by consumer. Color is probably the most difficult and important test to be made on flour and millers continues to maximise their profits and yields in their milling process.

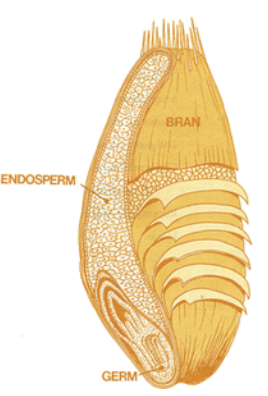

AKernel ofWheat

The kernel of wheat is a storehouse of nutrients and when mill into flour, food like bread, rolls, biscuits, muffins, pancakes, breakfast cereals, macaroni, spaghetti and noodles provides low cost nutrition, an essential human diet.

The endosperm is about 83% of the kernel and is the source of white flour. Bran is about 14% of the kernel and Germ, 3%.

Not all wheat is alike. There are more than 30,000 varieties of wheat, which fall into six major classes that are grown in the United States. The six classes are based on planting and harvesting dates, as well as hardness, color and shape of kernels. The classes are hard red spring, hard red winter, soft red winter, hard white wheat, soft white wheat and durum. Hard wheat is higher in protein and

gluten and is therefore usually used for yeast breads. Soft wheat makes very tender pastries, cakes, cookies, flatbreads, crackers and muffins. Soft and hard wheat are often blended to make all-purpose flour. The hardest wheat, durum is primarily used for making pasta.

Milling Process

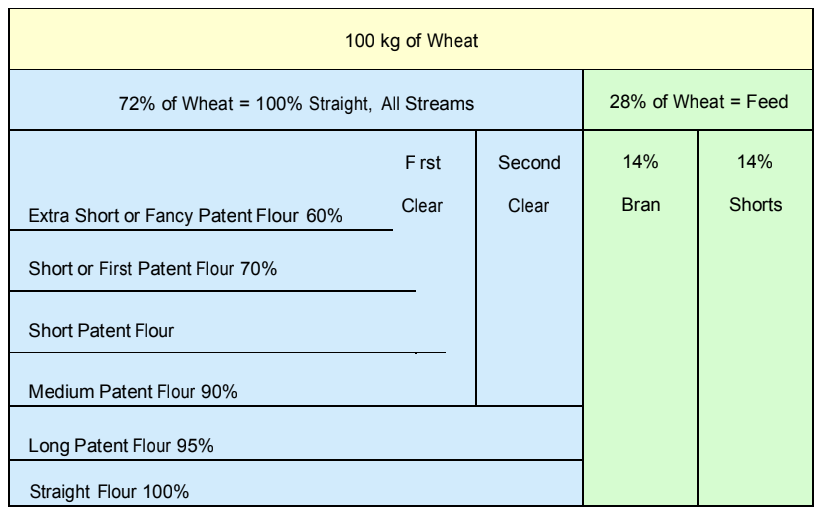

Milling is a process by which kernel components are separated physically and each milling process yields products indicative of the grain being milled. In the milling process, wheat is milled to remove bran and germ and reduce the wheat kernel to flour to be used in various baked and non-baked goods. Other products of the process includes mill feed, the material remaining after all the usable flour is extracted is used by the feed industry either directly or indirectly as a feed supplement. Generally a 100 kg of wheat will produce 72 kg of flour. In large flourmills, 30 or more flour streams of varying composition and purity may be collected, grouped and merchandised. Combining all stream results in a straight grade flours. The remaining streams contain more bran and germs are considered clear flour.

All-Purpose Flour

All-purpose flour is the finely ground endosperm of the wheat kernel separated from the bran and germ during the milling process. All-purpose flour is made from hard wheat or a combination of soft and hard wheat from which the home baker can make a complete range of satisfactory baked products such as yeast breads, cakes, cookies, pastries and noodles.

Enriched All-Purpose Flour has iron and B-vitamins added in amounts equal to or exceeding that of whole- wheat flour.

Bleached Enriched All-Purpose Flour is treated with chlorine to mature the flour, condition the gluten and improve the baking quality. The chlorine evaporates and does not destroy the nutrients but does reduce the risk of spoilage or contamination.

Unbleached Enriched All-Purpose Flour is bleached by oxygen in the air during an aging process and is off-white in color. Nutritionally, bleached and unbleached flour are the same.

Bleached all-purpose flour is exposed to chlorine gas or benzoyl peroxide to whiten and brighten flour color. Chlorine also affects baking quality by “maturing” or oxidizing the flour, which is beneficial for cake and cookie baking. The bleaching agents react and do not leave harmful residues or destroy nutrients.

UsingCR-410for Flour Measurement

For sample measurement, place flour in Granular Materials Attachment CR-A50 and flush it against the retaining ring. The ring is tapped to compress the flour evenly against the glass place.

Tighten CR-A50 cover and use the CR-410 to measure.

For repeatability, some users use the same weight of flour for sample presentation to ensure and maintains similar density.

Measure the Lab values of the flour.

CR-410 users in the Philippine Flour Industry

- Philippine Foremost Milling Corporation

- General Milling Corporation

- Liberty Flour Mill

- Asian Grain Mills

- San Miguel Flour Mills

- Wellington Flour Mills

- Mabuhay Interflour

- Gardenia Breads